I still remember the moment vividly.

An Italian businessman - impeccably dressed and a veteran in the furniture manufacturing world - came along and toured our factory. It was a few weeks before Christmas last year.

Let's just call this gentleman "Signore N".

Everything went smoothly. My colleague and I showcased our latest models, our BIFMA-compliant quality control processes, and our assembly workshop. Signore N seemed impressed.

Then we reached our injection moulding department.

"So, what surface finish standard do you use?" As Signore N examined an 800-tone machine, he turned to me with what seemed like a simple question, "do you use VDI?"

I froze.

VDI? Surface finish standard? The terms floated in the air as I scrambled for an answer.

I even asked the gentleman to clarify his question. but I was just as clueless as before.

After a minute of awkward silence…

"We'll need to check with our technical team on that," I managed to reply, making a mental note to research this mysterious "VDI" immediately.

The truth? I had no idea what he was talking about. And if you're anything like me, perhaps you don't either.

That's why I've dedicated this week's newsletter to a topic many of us in the commercial furniture space overlook but shouldn't: the VDI 3400 surface finish standard.

Introduction

By the end of this newsletter, you will have a much clearer understanding of how a mould's finish (surface appearance) is specified. You can then build stronger trust with your customers when they bring up the topic - remember, everything happens for a reason, especially when money is on the line. Even something as less obvious as the surface texture of an injection-moulded product has a lot of thoughts put into it.

A sidenote: I have come across the terms of "mould/mold" and "tooling" during my research on the topic. Although they are two separate words, they both refer to the one thing - the stuff we use to mass produce other stuff. The same applies to "texture" and "finish".

In other words,

mould/mold = tooling

texture = finish

Why do we want to add a surface finish to plastic parts?

Surface finish is a more professional term that refers to the texture of the surface of a product - or in this case, the surface of the moulding.

There are two main reasons why manufacturers would consider adding finish to the surface of mass-produced parts. For designers and marketers, the main concern is an aesthetic one. The appearance of the end-product has a direct impact on how it appeals to the consumers - a finished look raises the perceived value of the product to them.

The process of injection moulding will inevitably leave marks on the manufactured parts (flow lines, knit lines, sink marks and shadow marks are some of the visual side-effects of the injection moulding process). Applying finishing to the surface can effectively conceal these imperfections.

Apart from the aesthetic considerations, different surface finishes can improve the functionality of moulded parts. Choosing the right surface finish offers many properties to the part that enhance its functionality. These functional benefits include but aren't exclusive to:

- longer durability

- higher resistance to scratches

- improved gripping (with a rougher textured finish)

- better paint and sticker adhesion (e.g. a matte textured finish can easily hold the paint on it for an extended amount of time)

- preventing plastic defects (e.g. short shots and flash)

- helping trapped gases run off during the manufacturing stage

Why it's important to choose a surface finish standard?

Developing an injection mould is a costly business, so every aspect, including the surface finish, needs to be considered when designing a component. You need to put in extra care when the surface finish is an integral part of the design. It can add to the development cost in terms of time and money when it's done incorrectly.

As the final step of toolmaking, applying surface finish to the mould can either be done by hand or other methods like EDM (electrical discharge machining). It can be a labour-intensive process.

The impact of surface finish on the development cost of toolmaking cannot be overlooked. Other influencing factors on cost related to surface finish include:

- the type of plastic material used (e.g. materials such as polycarbonate (PC) and acrylic demand a higher level of polishing to reach a smooth and even finish than other materials)

- the tool steel (e.g. steel with a high hardness is needed to create a glossy finish)

Given the capital-intensive nature of injection mould development, it's better to work with an agreed-upon standard on surface finish to ensure it stays consistent on the plastic products. A standard can smooth out communication between the marketers, designers and engineers - with the end goal that the appearance and functionality stay consistent on the products.

Enter industrial standards like SPI (another international standard set by U.S.-based Plastics Industry Association, formerly called Society of the Plastics Industry), Mold-Tech, Yick Sang…

And VDI (more specifically, VDI 3400).

What is VDI 3400?

VDI 3400 is a mould texture standard set by the Society of German Engineers (Verein Deutscher Ingenieure, this is what VDI stands for). Although this standard is more likely to be used when the manufacturing process takes place or your end-users are located in Europe because of its German origin, the standard is just as globally recognised as other common specifications like SPI.

The surface finishes are given 45 grades of texture ranging from 0 to 45. They go from very smooth (lower numbers) to very rough finishes (higher numbers). Under the VDI 3400 standard, a part's surface finish can roughly fall into one of these three groups:

- VDI 0 to 15 (very smooth finishes) - usually for optical parts or high-gloss finishes

- VDI 18 to 30 (medium roughness) - suitable for most consumer parts

- VDI 33 to 45 (rough finishes) - for parts where appearance is less critical

If you want a specific roughness for the surface of a product, VDI 3400 is a more suitable standard to use with its wide-range and detailed gradation in roughness levels. At the same time, other surface finish standards categorise finishes differently. For example, the finish range of SPI stresses more on the method used to achieve the surface finish.

This is another reason why you should have a good understanding of specific needs of your client's project - to identify a suitable surface finish standard for the project.

So, whether to choose VDI 3400 or other surface finish standards requires you to consider the specific needs of your project, including:

- geographic preferences

- finish requirements

- product application

- cost and time

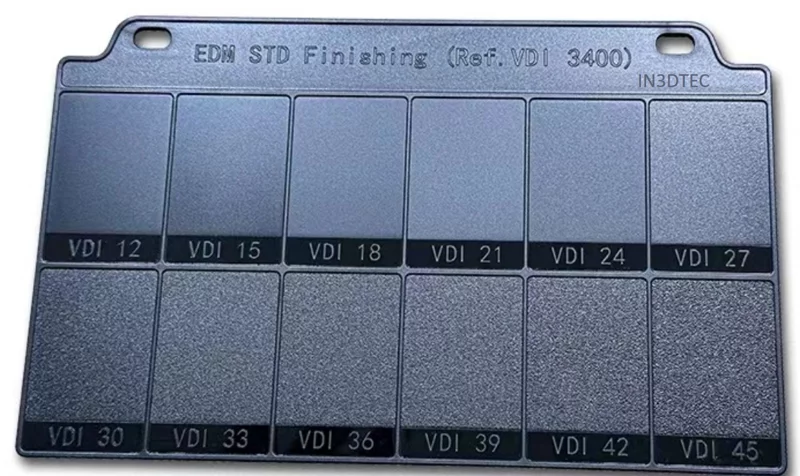

VDI 3400 Texture Card

If you work with a factory that offers injection moulding manufacturing and development services, chances are they will provide you with a palm-sized texture card for the industrial standard you want to work with (in this case, we're talking the VDI 3400 standard). The card gives you a handy reference to gauge for plastic mould textures.

Image Source: IN3DTEC

Final Thoughts

Signore N taught me an important lesson.

In the competitive world of contract-grade office furniture, technical knowledge matters just as much as design trends and price points.

Understanding standards like VDI 3400 helps position you as a trusted advisor rather than just a vendor - exactly the kind of relationship that leads to long-term partnerships and referrals.

I hope this overview helps you avoid the blank stare I experienced that day on the factory floor. As always, our team at Higi is here to support your success with the professional expertise (from development of new products to manufacturing) you need to excel.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.